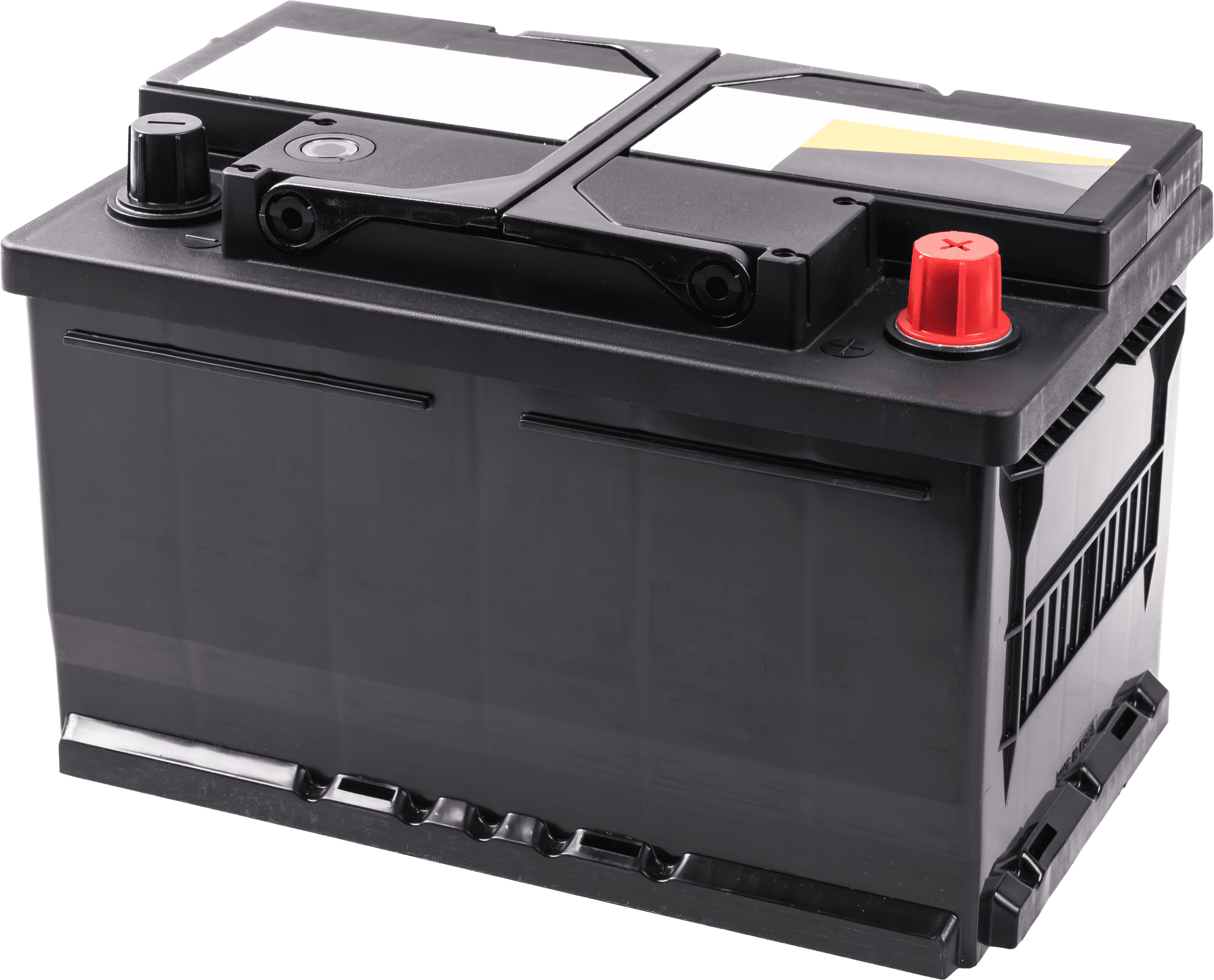

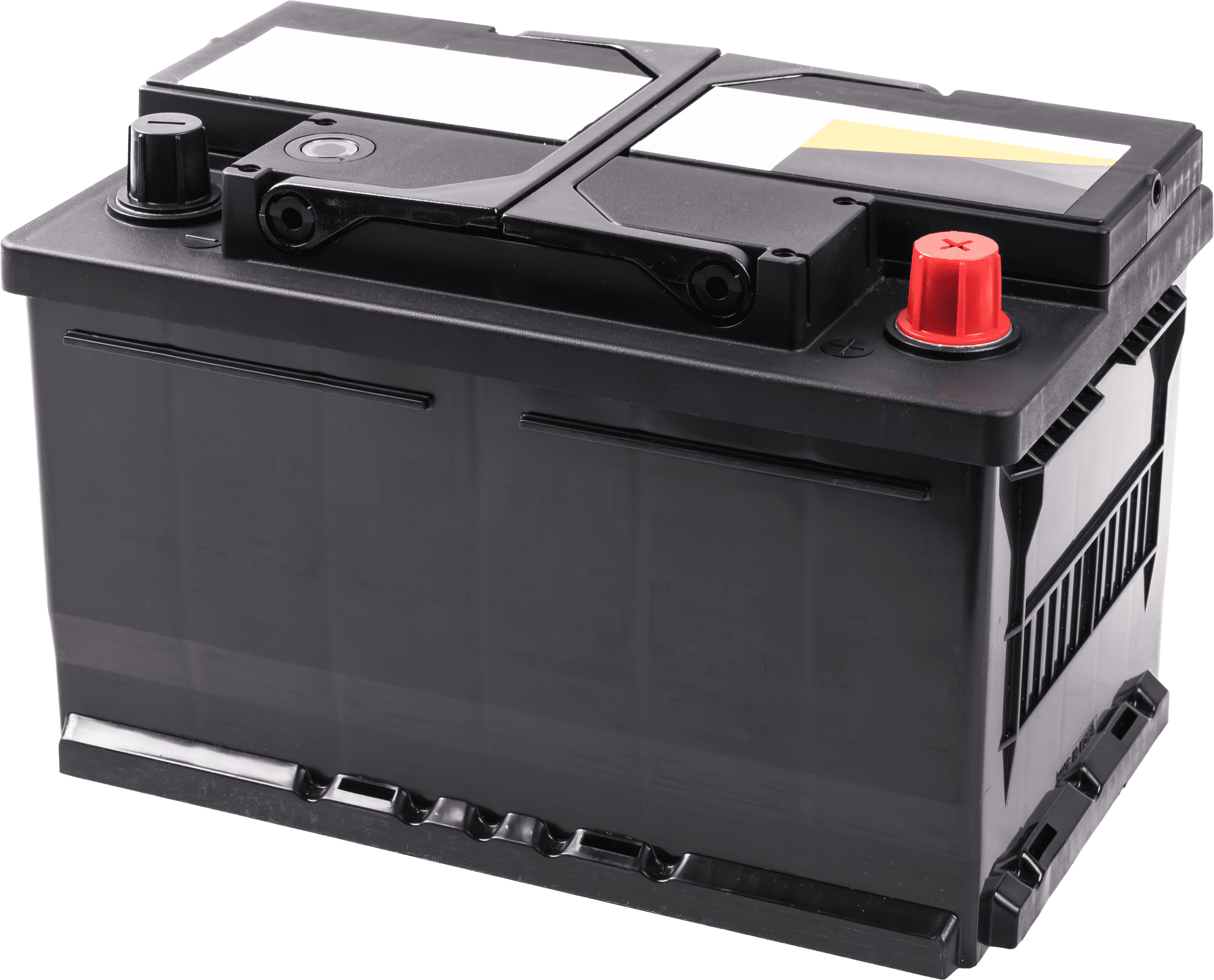

GME Battery Recycling Channel

Discover our best technology application in Battery Recycling. Here you can find our full implementation and hot commissioning videos of Recycling plants for waste management in different part of the world made by our Techincal Team on site, organized in chronological order

40 to 50 tpd Lead alloys Refinery

Sector: batteries recycling plant (full factory)

Commissioned: FABCOM SARL

Country: ALGERIA

Performed activities: Engineering, procurement, realization and installation supervision

Material: stainless steel AISI 304/316

Capacity of the plant: 80 Tons/day of exhausted batteries

25 Kg ingots casting machine 2019

15 to 20 tph BREAKER WITH PASTE INTO BIG BAGS

That’s what they said

“They helped us building a new Lead Recycling Plant and assisted during the Commissioning phase.”

“GME new Gravity Breaker has a great component’s separation!”