IMI Project Description

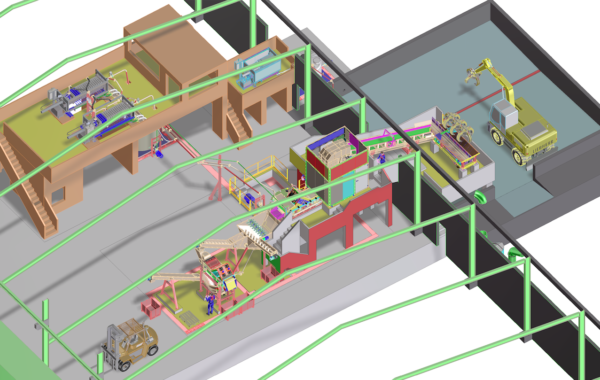

In 2016, the GME Recycling Company, signed the contract for the Battery Recycling Plant Project with IMI Company, Pakistan. In the project, which built a Battery Breaker plant with an annual capacity of 44,000 tons in Kotri, Sindh, Pakistan, our Engineers were responsible for the engineering, procurement, execution and the installation supervision.

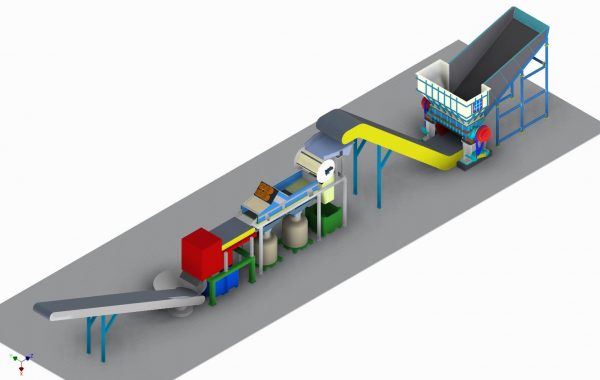

Factory supply for recycling of lead acid batteries with cap. 120 Tons / day, the supply includes 7 tons/hour battery breaker with:

7 m3 rotary furnace (max load 25 ton) with:

Projects specs

Sector: Batteries recycling plant (full factory)

Commissioned: IMI – (International Metal Industries Pvt, Ltd)

Country: PAKISTAN

Performed activities: Engineering, procurement, realization and installation supervision

Material: stainless steel AISI 304/316

Capacity of the plant:120 Tons/day of exhausted batteries

Automatic loading of the above furnace including to fillup the furnace in max 15 min.

N. 1 25 kg ingots casting belt, production capacity 12 tons/hour, with water cooling tower and with manual stacking by with monorail hoist and gripper.

N. 2 chain skimmers for dross removing

N. 2 stirrers for kettle bath stirring

N. 5 kettles capacity 40 and 25 tons for lead bullion refining to produce hard different alloy, soft alloy purity 99,985% and special alloy like calcium alloy.

N. 2 molten lead pumps for transferring between kettles

N.1 de-dusting system of the exhaust gas from rotary furnace and from kettles, composed by:

Discover our related recycling plants

Comments are closed.