Tianneng Project Description

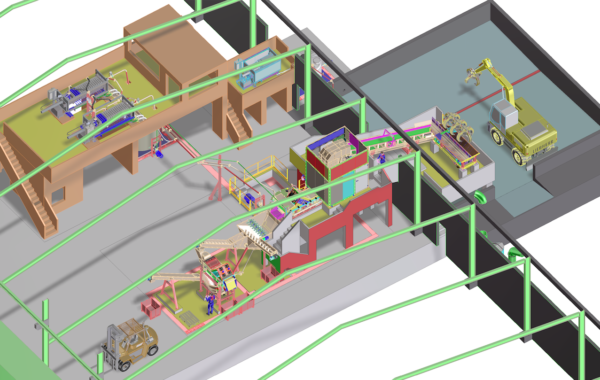

In 2011, GME’s Technical Team have been selected for a new Battery Recycling Plant Project from ZHEJIANG TIANNENG SOURCE MATERIAL CO., LTD, P. R. now TIANNENG Group, the leading enterprise of the new energy power battery in China. Its comprehensive strength ranks among the global top 500 new energy enterprises, top 500 Chinese enterprises, top 500 Chinese private enterprises and top 10 Chinese battery industry. > The project consisted in a complete Battery Breaker plant manufacturing with a capacity of 25 tons/hour in Changxin county, Huzhou, Zhejiang. GME Technical Team were responsible for the engineering, procurement, manufacturing and the installation supervision of the entire plant.

Performed activities: 2011, battery recycling plant cap. 150.000 tpy supplying, with

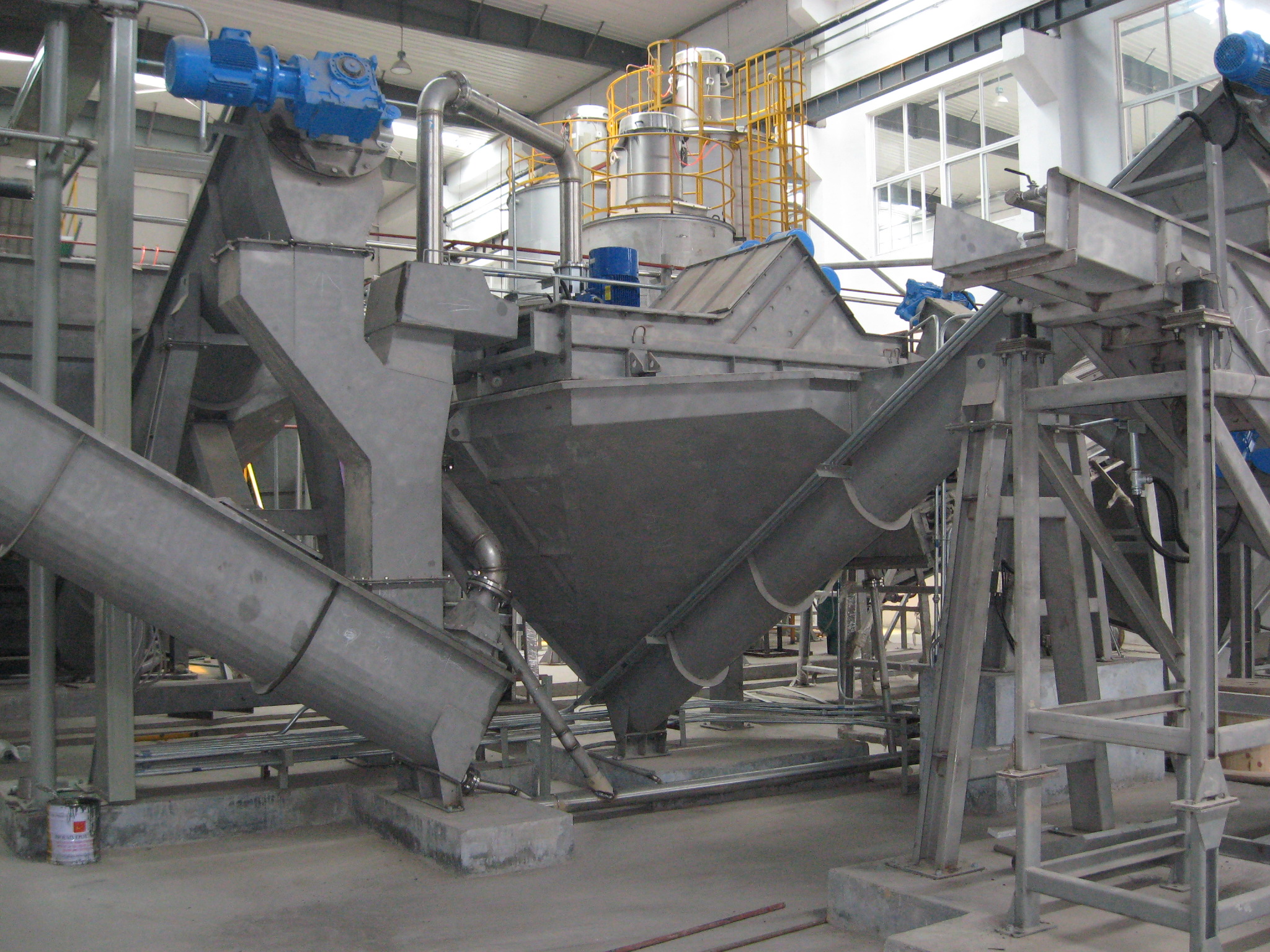

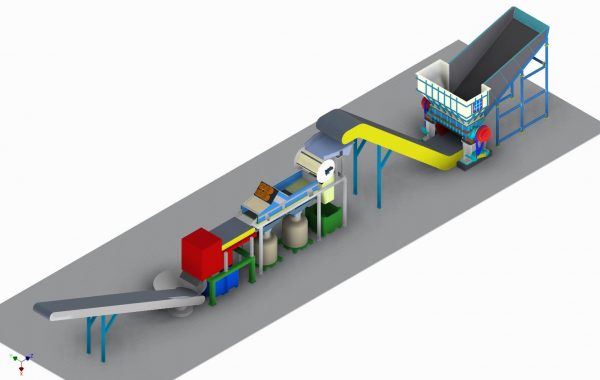

Battery breaker unit, 25 tph capacity, including

Paste de-sulphuration unit, 400 tpd capacity, including:

Projects specs

Sector: batteries recycling plant

Commissioned: ZHEJIANG TIANNENG SOURCE MATERIAL CO., LTD – now TIANNENG Group.

Country: Changxin county, Huzhou,Zhejiang, P. R. China

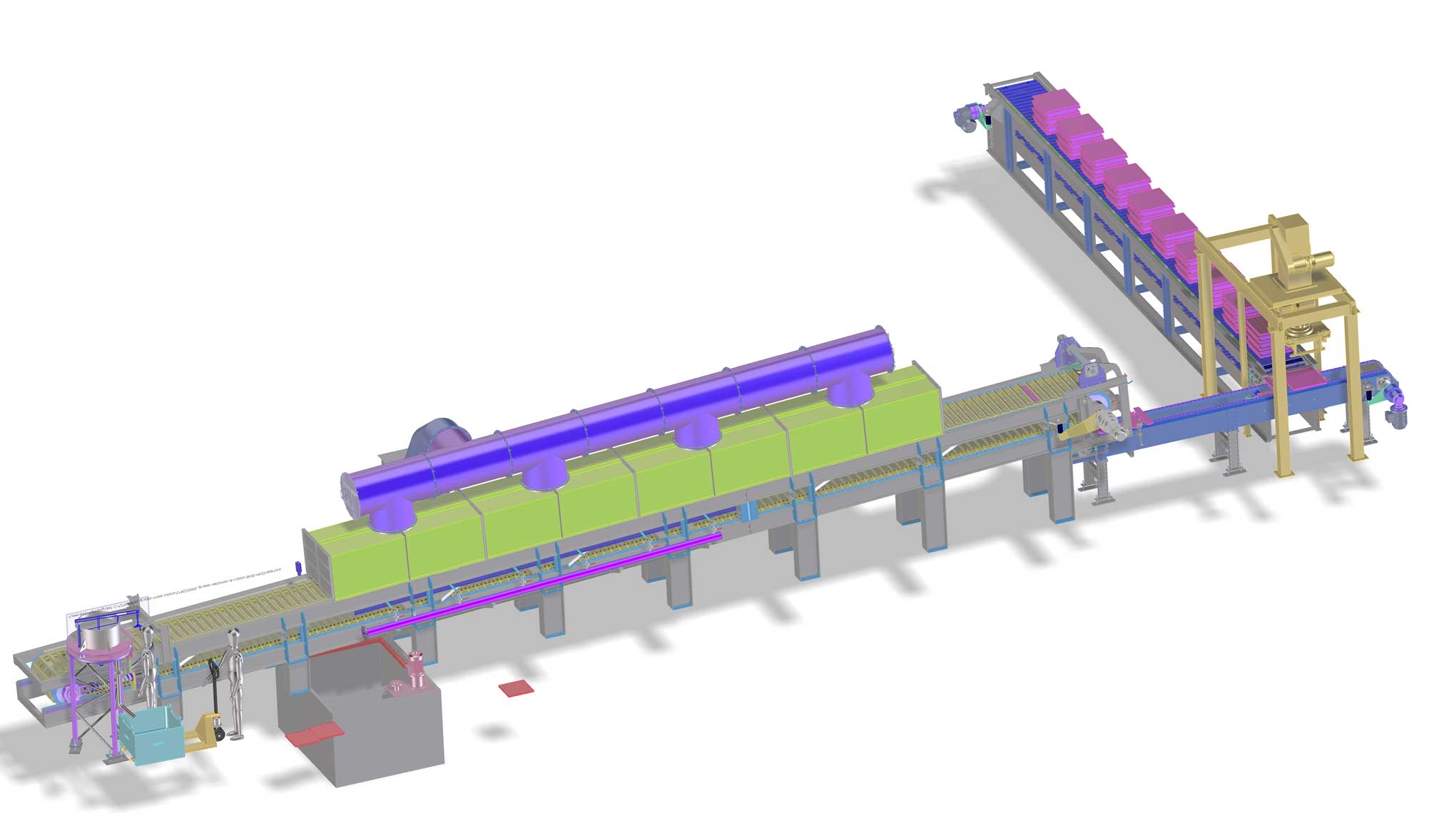

Performed activities: Battery recycling plant cap. 150.000 tpy supplying, with battery breaker, paste de-sulphuration unit, 2 rotary furnaces 12 M3/each, 6 kettles 120 Ton/each, 1 ingots casting belt.

Capacity of the plant: 150.000 tpy

Twin rotary furnaces 12 m3 capacity (30 ton)

N.6 kettles 120 Ton, including:

N.1 ingots casting belt, 20 ton per hour capacity with 25 kg ingots

N.1 variable speed casting belt with:

Discover our related recycling plants

Comments are closed.