In the ever-growing pursuit of sustainable solutions, a novelty from GME R&D has emerged to transform the way we recycle batteries. The Gravity Breaker was born with a strong natural footprint as a consequence of the continuous pursuit of efficient and eco-friendly solutions to recycle Used Lead Acid Batteries – otherwise why recycling something if we have to squander something else?!

In a nutshell, the technology massively exploits natural forces to reduce the usage of Electricity and Water. GME R&D crafted an advanced system in waste reduction and cutting-edge separation process, with an automated control to ensures precise separation without compromising the quality. Join us as we delve into the world of battery recycling and explore the remarkable capabilities of Gravity Breaker. Prepare to be amazed by this cutting-edge solution that is revolutionizing the recycling industry.

GME’s Gravity Battery Breaker: how it works

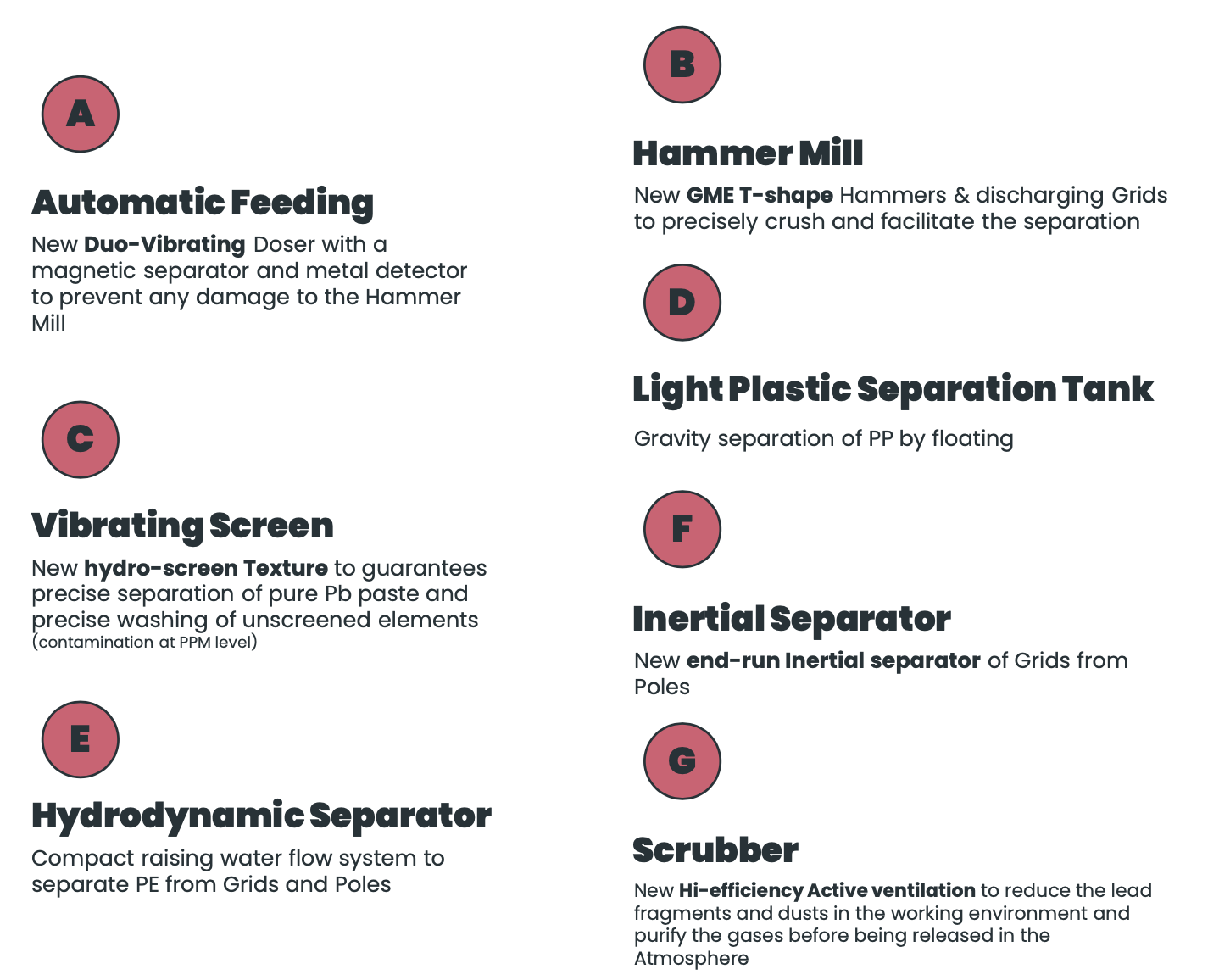

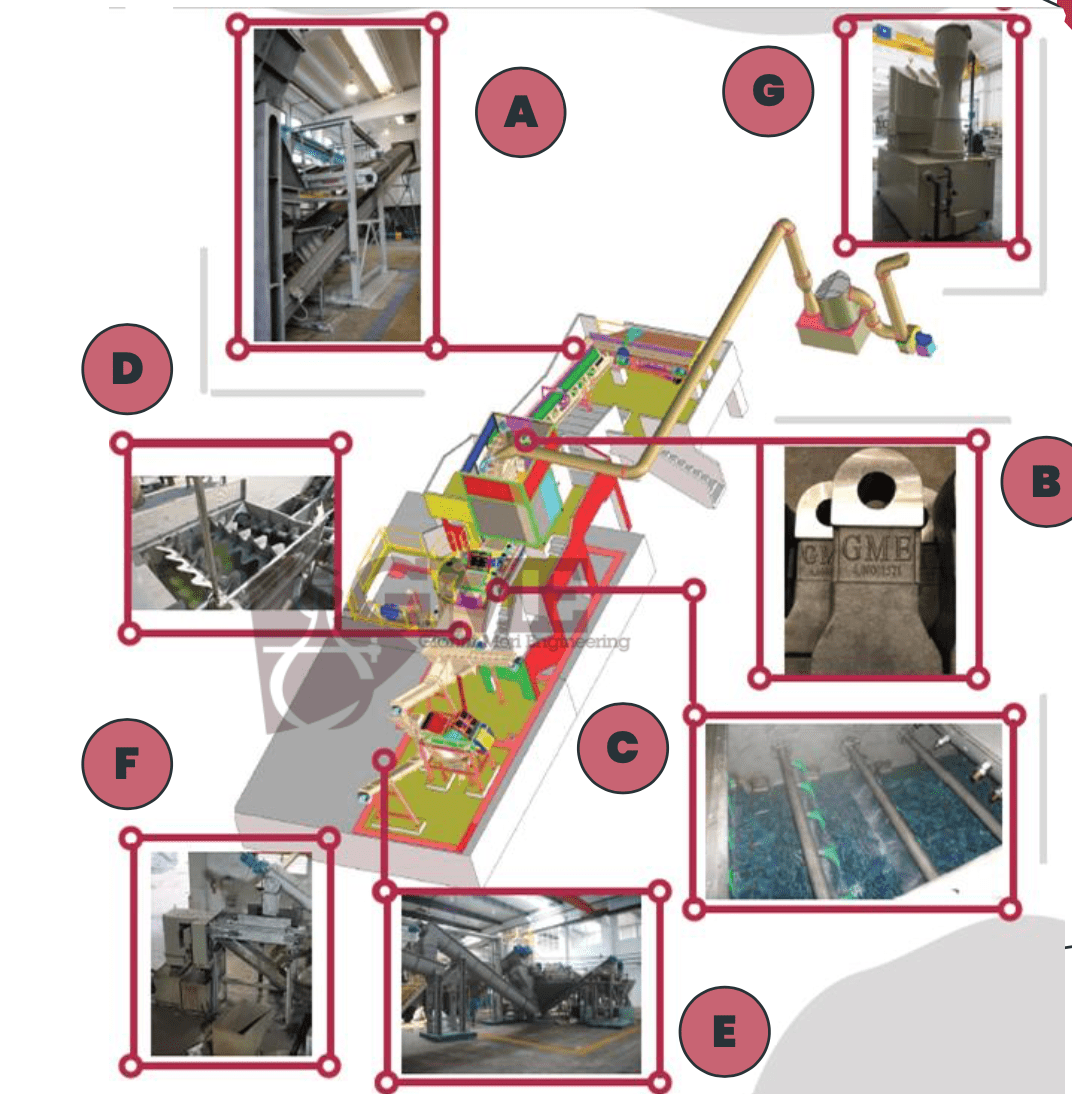

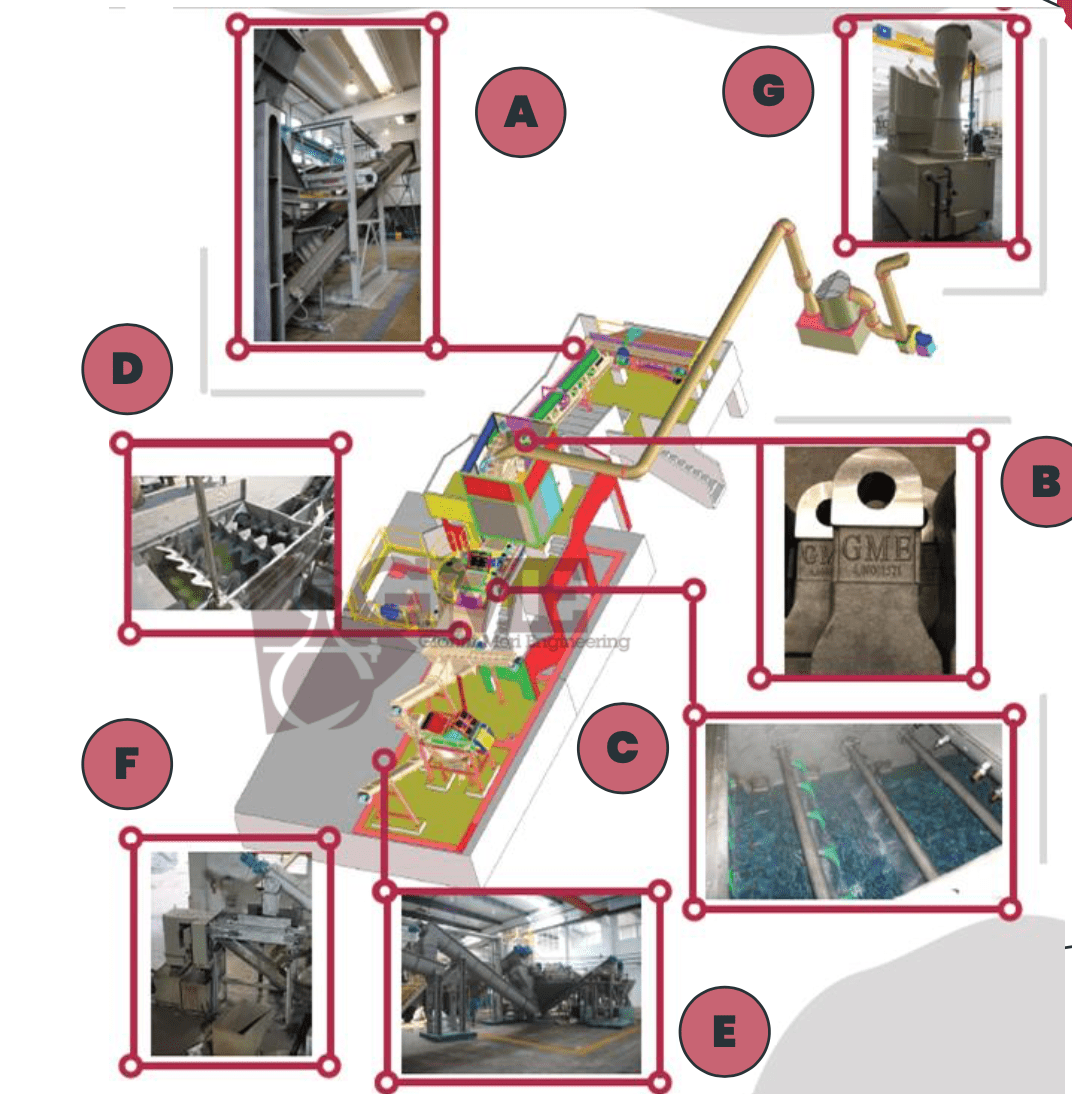

The technology is leveraging on natural forces such as Gravity and Inertial Mass in every key separation process, perfectly balanced over the entire chain with an innovative GME process to obtain the separation of all the 5 elements composing a ULAB (PP, PE, Pb paste, Grids, Poles) keeping our highest quality while reducing:

- Waste formation

- Sulphur presence in the DS Pb paste

- Smelting and Refinery time and cost

giving a new ecological turn to the Recycling path!

Harnessing natural forces for sustainable battery breaking

The Gravity Breaker technology is transforming the battery recycling industry by harnessing natural forces for sustainable battery breaking. This smart approach utilizes gravity to break down batteries, eliminating the need for energy-intensive processes and reducing environmental impact. By utilizing the force of gravity, the Gravity Breaker technology avoids the use of harmful chemicals and excessive energy consumption associated with traditional battery breaking methods. The system operates by dropping batteries into a specially designed chamber where they are subjected to controlled gravitational forces that improves the precision of breaking into their constituent parts. This innovative approach not only ensures efficient and effective battery breaking but also promotes sustainability by minimizing waste and resource consumption. With the Gravity Breaker technology, the battery recycling industry is taking a significant step towards a more environmentally friendly and sustainable future.

Automated Feeding: Ensuring Precise Separation without Damage

In the quest for efficient and sustainable battery recycling, one crucial aspect is the precise separation of different battery components. This is where the innovative Gravity Breaker technology truly shines. With its automated feeding system, it guarantees a meticulous separation process. The automated feeding system ensures a consistent and controlled supply, one by one, of batteries into the Gravity Breaker, eliminating the risk of jams or uneven distribution. By carefully regulating the flow, this technology allows for precise separation of components like metal casings, electrodes, and electrolytes. This not only maximizes the recovery of valuable materials but also reduces waste and minimizes environmental impact. Gravity battery Breaker’s automated feeding system is a testament to the dedication of researchers and engineers in revolutionizing battery recycling, ensuring that every step of the process is efficient, sustainable, and environmentally friendly.

Cutting-Edge Separation Processes: From Hammer Mill to Vibrating Screen

The Gravity battery Breaker technology brings a revolution in battery recycling, and at the heart of this innovation lies the cutting-edge separation processes from the hammer mill to the scrubber. The hammer mill, with its powerful heavy duty hammers, shreds batteries into smaller pieces, facilitating subsequent separation. The Vibrating Screen then comes into play, using water and agitation to separate the shredded materials based on their specific gravity. This process effectively separates heavy metals like lead and nickel from plastics and other lighter materials, ensuring optimal recycling outcomes. With its new Power Wash technology, the separation process is meticulous enhanced, while is effectively deeply washing the elements to reduce its contamination. the Gravity Breaker technology sets a new standard in battery recycling, guaranteeing not only environmental sustainability but also economic viability for the industry.

NEW Power Wash: Advancements in Waste Reduction

Introducing our revolutionary new Power Wash system! With cutting-edge features including an Ultra High-pressure separation process and the innovative GME honeycomb vibrating screen, this system is designed to extract Pb paste while efficiently separating the AGM. Our 6.5 bar Ultra pressure system ensures thorough fragmentation of Fiber ceramic, preventing metallic fractions and eliminating the dreaded WOOL SWAB effect.

With its Plug&play solution, our system guarantees 24/7 operativity, saving you time and effort. Say goodbye to preselecting and extracting the AGM portion from the mix—our Power Wash system handles it all effortlessly. Plus, our nozzles are meticulously crafted with a 48° Water Blade System, constructed entirely in Stainless Steel for durability and performance you can rely on. Upgrade to the future of Power Wash technology today!

NEW Lithium Guard: Artificial Intelligence in the Lead Battery Recycling!

Introducing our cutting-edge Visual AI Traceability system, designed to revolutionize your scrap detection process. Here’s what sets us apart: Unrivaled Precision:

Achieve maximum precision with our advanced technology, capable of detecting objects as small as 2 cm in any shape.

Lightning-fast Detection: Experience ultra-detecting speeds of up to 6 m/sec, allowing for the processing of up to 60 tons per hour (TPH) of scrap material.

Seamless Integration: Our Plug&play solution ensures 24/7 operativity, providing you with uninterrupted performance whenever you need it. Plus, our intuitive AI Dashboard allows for easy monitoring and optimization of input flow, complete with trend analysis and cost optimization tools.

Flexible Rental Options: Get started with our system with rental solutions starting from just €30k per year, offering a cost-effective alternative to full-time equipment ownership. Upgrade to the future of scrap detection with our Visual AI Traceability system

The Gravity Breaker technology has the potential to revolutionize battery recycling, offering a sustainable solution that harnesses natural forces for efficient and environmentally friendly waste reduction. With its automated feeding system and cutting-edge separation processes, this innovative technology ensures precise separation without causing damage. As we continue to strive for a greener future, it is crucial to invest in advancements like the Gravity Breaker that address the growing issue of battery waste. However, while this technology presents a significant step forward, it also raises questions about the broader impact of battery production and consumption on our environment. As we celebrate this breakthrough, let us also reflect on the need for a comprehensive approach to tackle the entire lifecycle of batteries, from production to recycling, and explore ways to further reduce our reliance on these energy sources altogether.

Comments are closed.